Woven Wire Cloth

Dorstener Wire Tech offers a full line of woven wire cloth and woven mesh products to meet the requirements for a wide range of applications. We manufacture and supply custom wire cloth of all varieties including plain, twilled, dutch, and reverse dutch. DWT designs woven wire cloth to meet specific product requirements, reducing clients’ costs and increasing production efficiencies. Our affiliate weaving and mills manufacture woven wire cloth and mesh to meet clients’ internal specifications, ISO, ASTM, and DIN standards.

Dorstener is ISO 9001 certified and most of our woven wire cloth products can be supplied in DFAR or Non-DFAR compliant materials. We stock a full range of stainless steel wire cloth including 304ss and 316ss woven wire cloth products.

Woven wire cloth is extremely versatile with applications ranging from hi-tech filtration to insect screening. The list of applications is endless including sifting, filtering, carrying, protecting, strengthening, designing, and classifying. In addition, DWT can supply extra wide woven wire cloth products up to 240” wide and in extra long rolls up to 2000’ LNF for certain roll specifications.

Our products comply with ASTM E2016 as a minimum. Our standard stock item specifications include:

- Market Grade

- Mill Grade

- Tensile Bolting Cloth

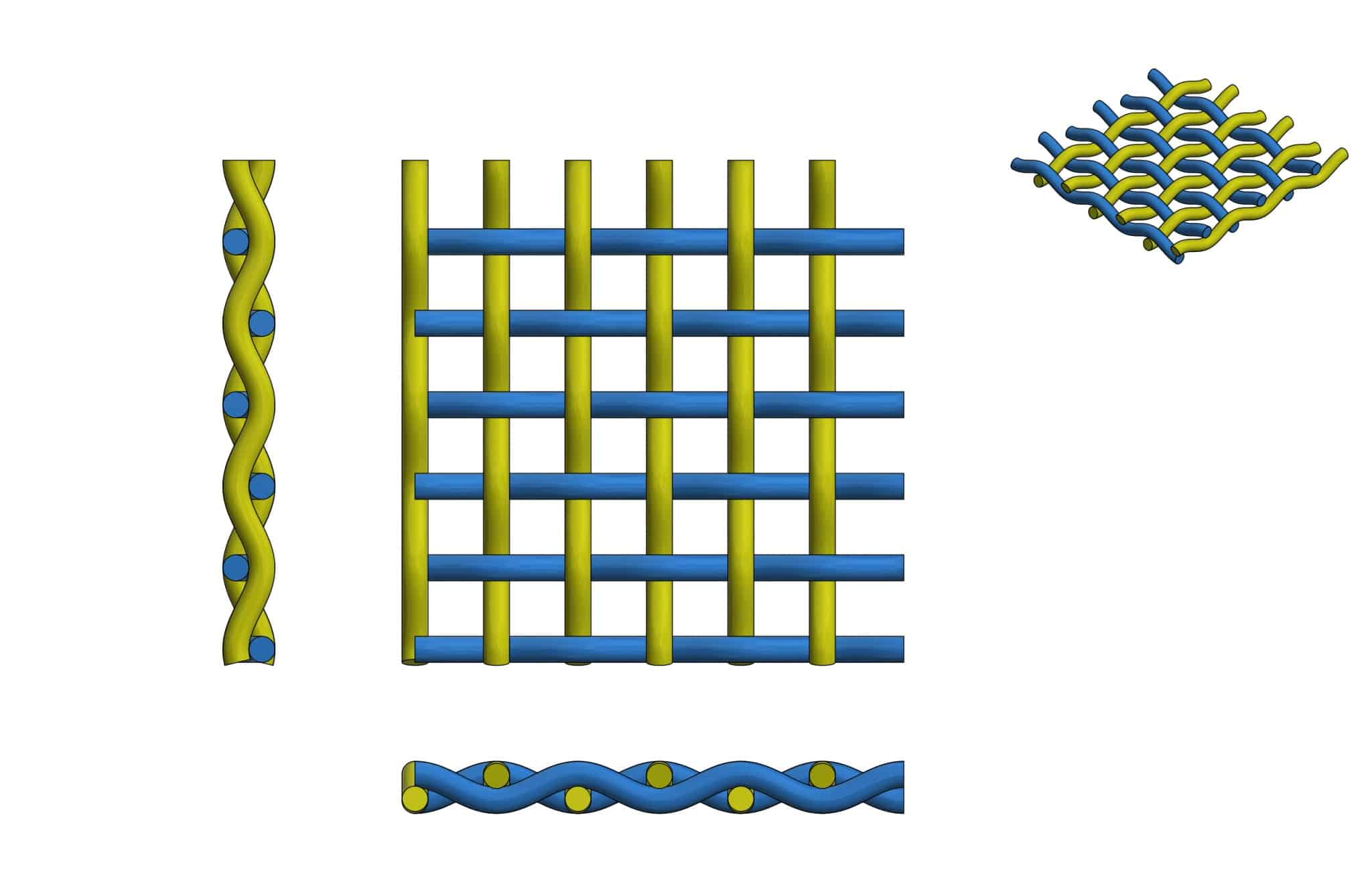

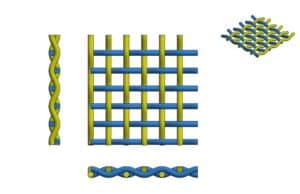

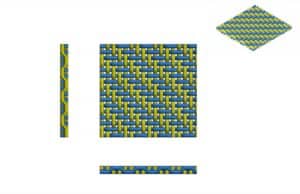

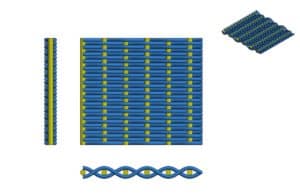

Plain & Twill Weave Woven Wire Cloth

These weaves are the most economical and are often used for sifting and sizing, particle separation, filtering, safety, and security applications. Dorstener Wire Tech offers these in a wide range of specifications, alloys, and grades. DWT manufactures plain and twill weave wire cloth to customer specifications.

Plain weave wire cloth is woven by alternating the shute wire over and under the warp wire, creating a wire mesh. Twill weave wire cloth is woven by passing the shute wire over and under two warp wires, creating a sturdier weave. This weave allows for the use of heavier wires, producing a stronger wire mesh.

Both weaves are economical – the plain weave being the most common and economical to produce. Uses of wire mesh include:

- Sizing

- Particle separation and filtering

- Particulate sifting

- Safety and equipment protection.

Industries served include aerospace, automotive, construction and oil & gas.

DWT’s custom manufacturing services include:

- Wide selection of metals and alloys, including special wire selections such as cable mesh and plastic-coated wire.

- Extra wide woven wire cloth, up to 240″ width for selected items.

- Woven wire cloth in long rolls, up to 2000’ long coils or rolls with no seams.

- Woven edges.

- Full range of conversion services, including slitting, shearing, calendaring, stretching and annealing.

- Oblong opening and high aspect ratio wire cloth designs are available.

DWT maintains the highest quality standards and is ISO 9001:2008 certified. All of our wire cloth products can be supplied in DFAR-compliant materials and meet or exceed ASTM standards. For a quick quote on our plain and twill weave woven wire cloth capabilities, contact us today.

Plain & Twill Weave Woven Wire Cloth Standard Grades & Specifications

The tables below shows the standard grades and specifications available for DWT’s Plain and Twill weave woven wire cloth.

| wdt_ID | Weave | Grade | Mesh | Wire Dia. (in) | Opening Width (in) | % of Open Area | Weight. per 100 sq.ft. | Opening (μm) |

|---|---|---|---|---|---|---|---|---|

| 1 | PLAIN | Industrial | 2 X 2 | 0.08 | 0.42 | 70.60 | 84.00 | 10668 |

| 2 | PLAIN | Market | 2 X 2 | 0.06 | 0.44 | 76.40 | 52.10 | 11100 |

| 3 | PLAIN | Industrial | 2 X 2 | 0.05 | 0.45 | 79.60 | 38.30 | 11328 |

| 4 | PLAIN | Industrial | 3 X 3 | 0.08 | 0.25 | 57.80 | 125.90 | 6435 |

| 5 | PLAIN | Industrial | 3 X 3 | 0.07 | 0.26 | 61.50 | 102.00 | 6638 |

| 6 | PLAIN | Industrial | 3 X 3 | 0.06 | 0.27 | 65.80 | 78.10 | 6866 |

| 7 | PLAIN | Market | 3 X 3 | 0.05 | 0.28 | 70.20 | 57.40 | 7095 |

| 8 | PLAIN | Industrial | 3 X 3 | 0.05 | 0.29 | 73.80 | 43.50 | 7273 |

| 9 | PLAIN | Mill | 3 X 3 | 0.04 | 0.29 | 76.90 | 33.10 | 7425 |

| 10 | PLAIN | Industrial | 4 X 4 | 0.12 | 0.13 | 27.00 | 377.80 | 3302 |

| 11 | PLAIN | Industrial | 4 X 4 | 0.11 | 0.14 | 33.60 | 289.30 | 3683 |

| 12 | PLAIN | Industrial | 4 X 4 | 0.09 | 0.16 | 39.90 | 222.10 | 4013 |

| 13 | PLAIN | Industrial | 4 X 4 | 0.08 | 0.17 | 46.20 | 167.90 | 4318 |

| 14 | PLAIN | Industrial | 4 X 4 | 0.07 | 0.02 | 50.70 | 136.00 | 4521 |

| 15 | PLAIN | Industrial | 4 X 4 | 0.06 | 0.19 | 56.00 | 104.10 | 4750 |

| 16 | PLAIN | Industrial | 4 X 4 | 0.05 | 0.20 | 61.50 | 76.50 | 4978 |

| 17 | PLAIN | Market | 4 X 4 | 0.05 | 0.20 | 65.90 | 58.00 | 5156 |

| 18 | PLAIN | Industrial | 4 X 4 | 0.04 | 0.21 | 69.90 | 44.10 | 5309 |

| 19 | PLAIN | Mill | 4 X 4 | 0.04 | 0.22 | 74.00 | 32.10 | 5461 |

| 20 | PLAIN | Industrial | 4 X 4 | 0.03 | 0.22 | 76.00 | 26.90 | 5537 |

| 21 | PLAIN | Industrial | 4 X 4 | 0.03 | 0.22 | 78.90 | 20.60 | 5639 |

| 22 | PLAIN | Industrial | 4 X 4 | 0.03 | 0.23 | 81.00 | 16.40 | 5715 |

| 23 | PLAIN | Industrial | 5 X 5 | 0.06 | 0.14 | 46.90 | 130.20 | 3480 |

| 24 | PLAIN | Industrial | 5 X 5 | 0.05 | 0.15 | 53.30 | 95.60 | 3708 |

| 25 | PLAIN | Industrial | 5 X 5 | 0.05 | 0.15 | 58.50 | 72.50 | 3886 |

| 26 | PLAIN | Market | 5 X 5 | 0.04 | 0.16 | 63.20 | 55.10 | 4039 |

| 27 | PLAIN | Industrial | 5 X 5 | 0.04 | 0.17 | 68.10 | 40.20 | 4191 |

| 28 | PLAIN | Mill | 5 X 5 | 0.03 | 0.17 | 70.60 | 33.60 | 4267 |

| 29 | PLAIN | Industrial | 6 X 6 | 0.06 | 0.10 | 38.70 | 156.20 | 2633 |

| 30 | PLAIN | Industrial | 6 X 6 | 0.05 | 0.11 | 45.70 | 114.80 | 2862 |

| 31 | PLAIN | Industrial | 6 X 6 | 0.05 | 0.12 | 51.60 | 86.90 | 3040 |

| 32 | PLAIN | Industrial | 6 X 6 | 0.04 | 0.13 | 56.90 | 66.20 | 3192 |

| 33 | PLAIN | Market | 6 X 6 | 0.04 | 0.13 | 62.40 | 48.20 | 3344 |

| 34 | PLAIN | Industrial | 6 X 6 | 0.03 | 0.14 | 65.30 | 40.30 | 3421 |

| 35 | PLAIN | Mill | 6 X 6 | 0.03 | 0.14 | 69.20 | 30.90 | 3522 |

| 36 | PLAIN | Market | 7 X 7 | 0.04 | 0.11 | 57.00 | 56.20 | 2740 |

| 37 | PLAIN | Industrial | 7 X 7 | 0.03 | 0.11 | 60.20 | 47.00 | 2816 |

| 38 | PLAIN | Mill | 7 X 7 | 0.03 | 0.12 | 64.60 | 36.00 | 2917 |

| 39 | PLAIN | Industrial | 8 X 8 | 0.06 | 0.06 | 24.60 | 208.30 | 1575 |

| 40 | PLAIN | Industrial | 8 X 8 | 0.05 | 0.07 | 32.30 | 153.00 | 1803 |

| 41 | PLAIN | Industrial | 8 X 8 | 0.05 | 0.08 | 38.90 | 115.90 | 1981 |

| 42 | PLAIN | Industrial | 8 X 8 | 0.04 | 0.08 | 45.20 | 88.20 | 2134 |

| 43 | PLAIN | Industrial | 8 X 8 | 0.04 | 0.09 | 51.80 | 64.30 | 2286 |

| 44 | PLAIN | Industrial | 8 X 8 | 0.03 | 0.09 | 55.40 | 53.70 | 2362 |

| 45 | PLAIN | Market | 8 X 8 | 0.03 | 0.10 | 60.20 | 41.10 | 2464 |

| 46 | PLAIN | Mill | 8 X 8 | 0.03 | 0.10 | 64.00 | 32.80 | 2540 |

| 47 | PLAIN | Industrial | 9 X 9 | 0.04 | 0.07 | 39.80 | 99.20 | 1781 |

| 48 | PLAIN | Industrial | 9 X 9 | 0.04 | 0.08 | 46.90 | 72.30 | 1933 |

| 49 | PLAIN | Industrial | 9 X 9 | 0.03 | 0.08 | 50.70 | 60.50 | 2009 |

| 50 | PLAIN | Industrial | 9 X 9 | 0.03 | 0.08 | 56.00 | 46.30 | 2111 |

| Weave | Grade | Mesh | Wire Dia. (in) | Opening Width (in) | % of Open Area | Weight. per 100 sq.ft. | Opening (μm) |

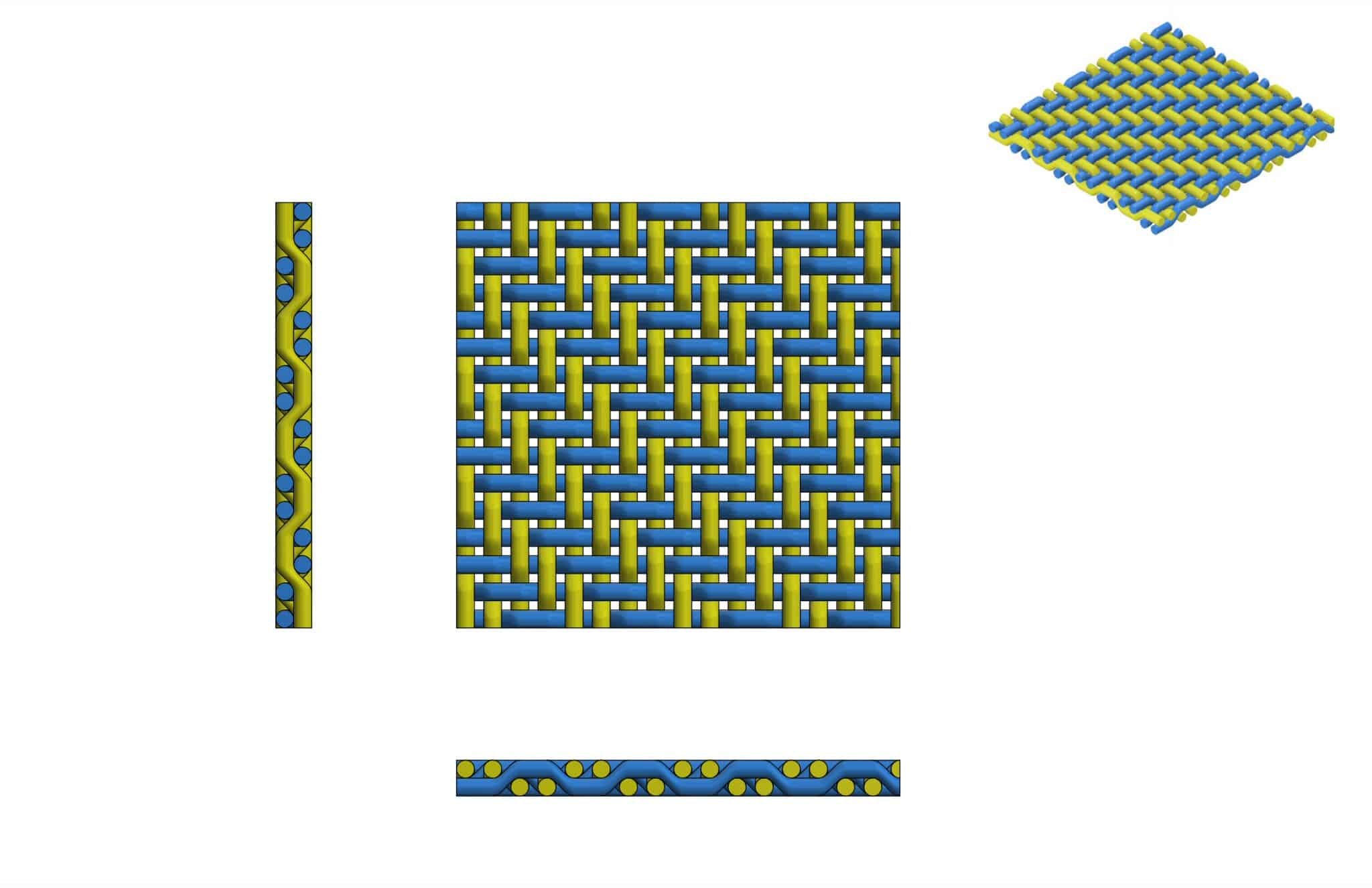

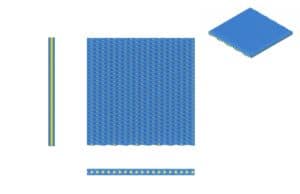

Plain Dutch Weave & Twill Dutch Weave Woven Wire Cloth

DWT manufactures custom woven wire cloth to meet clients’ filtration needs. Dutch weave filter mesh provides superior filtration capabilities for a wide range of applications including, pressure, fuel and liquid filters for aerospace, petrochemical, pharmaceutical, mining, and waste water treatment industries.

Twill Dutch weave woven wire cloth combines Dutch and twill weaving to provide a fine mesh filtering cloth. Shute wires are passed over and under two warp wires, providing a tight, fine filter with tapered openings. The weaving process allows for the use of very fine wires, produce filtering mesh for gas and liquid applications.

Dorstener Wire offers custom wire configurations for woven wire cloth to meet the specific needs of our clients. For Dutch weaves, micron-grade wire is most commonly used. In addition, DWT has the capability to manufacture extra long roll or coils up to 800’ with no seams and extra wide widths up to 120”.

We offer a wide range of metals and alloys to provide the best material or combination of materials for the filter mesh.

A full range of conversion services are available. These include slitting, shearing, annealing and stretching. DWT can also provide information on the filtration performance of the mesh to ensure it meets product requirements.

Dorstener Plain Dutch and Twill Dutch weave woven wire cloth products are in compliance with ISO 9001:2008 and ASTM standards. Most are available in DFARS-compliant materials. DWT will also manufacture to ISO, DIN and client requirements. Our expert staff is available to help you select or design the most effective wire cloth product for your application. Contact us today to learn more.

Plain Dutch Weave & Twill Dutch Weave Woven Wire Cloth Specifications

The table below shows the standard specifications for DWT’s Plain Dutch and Twill Dutch weave woven wire cloth.

* Indicated Glass Bead Test / Not Geometric Calculation

| wdt_ID | Weave | Mesh | Warp Wire (in) | Shute Wire (in) | Geometric Opening μm (per ASTM E2814) | Nom μm Rating | Approx Wt per 100 sq/ft |

|---|---|---|---|---|---|---|---|

| 1 | PDW | 8x85 | 0.0140 | 0.0126 | 298 | 310 | 53 |

| 2 | PDW | 12X64 | 0.0240 | 0.0165 | 284 | 300 | 80 |

| 3 | PDW | 14X88 | 0.0200 | 0.0130 | 225 | 250 | 64 |

| 4 | PDW | 16X80 | 0.0169 | 0.0134 | 213 | 200 | 63 |

| 5 | PDW | 24X110 | 0.0150 | 0.0100 | 137 | 110 | 52 |

| 6 | PDW | 30X150 | 0.0090 | 0.0070 | 113 | 90 | 31 |

| 7 | PDW | 40X200 | 0.0070 | 0.0055 | 85 | 70 | 27 |

| 8 | PDW | 50X250 | 0.0055 | 0.0045 | 68 | 55 | 21 |

| 9 | PDW | 80X400 | 0.0050 | 0.0030 | 50 | 40 | 17 |

| 10 | TDW | 30X250 | 0.0100 | 0.0080 | 114 | 90 | 64 |

| 11 | TDW | 80X700 | 0.0040 | 0.0030 | 42 | 35 | 25 |

| 12 | B-TDW | 120X400 | 0.0040 | 0.0025 | 49* | 45 | 15 |

| 13 | B-TDW | 165X800 | 0.0028 | 0.0020 | 30* | 25 | 14 |

| 14 | B-TDW | 200X600 | 0.0024 | 0.0018 | 35* | 30 | 10 |

| 15 | TDW | 165X1400 | 0.0028 | 0.0016 | 26 | 10 | 16 |

| 16 | TDW | 200X1400 | 0.0028 | 0.0016 | 15 | 5 | 16 |

| 17 | TDW | 325X2300 | 0.0014 | 0.0010 | 9 | 2 | 9 |

| 18 | TDW | 400X2800 | 0.0010 | 0.0008 | 7 | 1 | 9 |

| 19 | PDW | 8x85 | 0.0140 | 0.0126 | 298 | 310 | 53 |

| 20 | PDW | 12X64 | 0.0240 | 0.0165 | 284 | 300 | 80 |

| Weave | Mesh | Warp Wire (in) | Shute Wire (in) | Geometric Opening μm (per ASTM E2814) | Nom μm Rating | Approx Wt per 100 sq/ft |

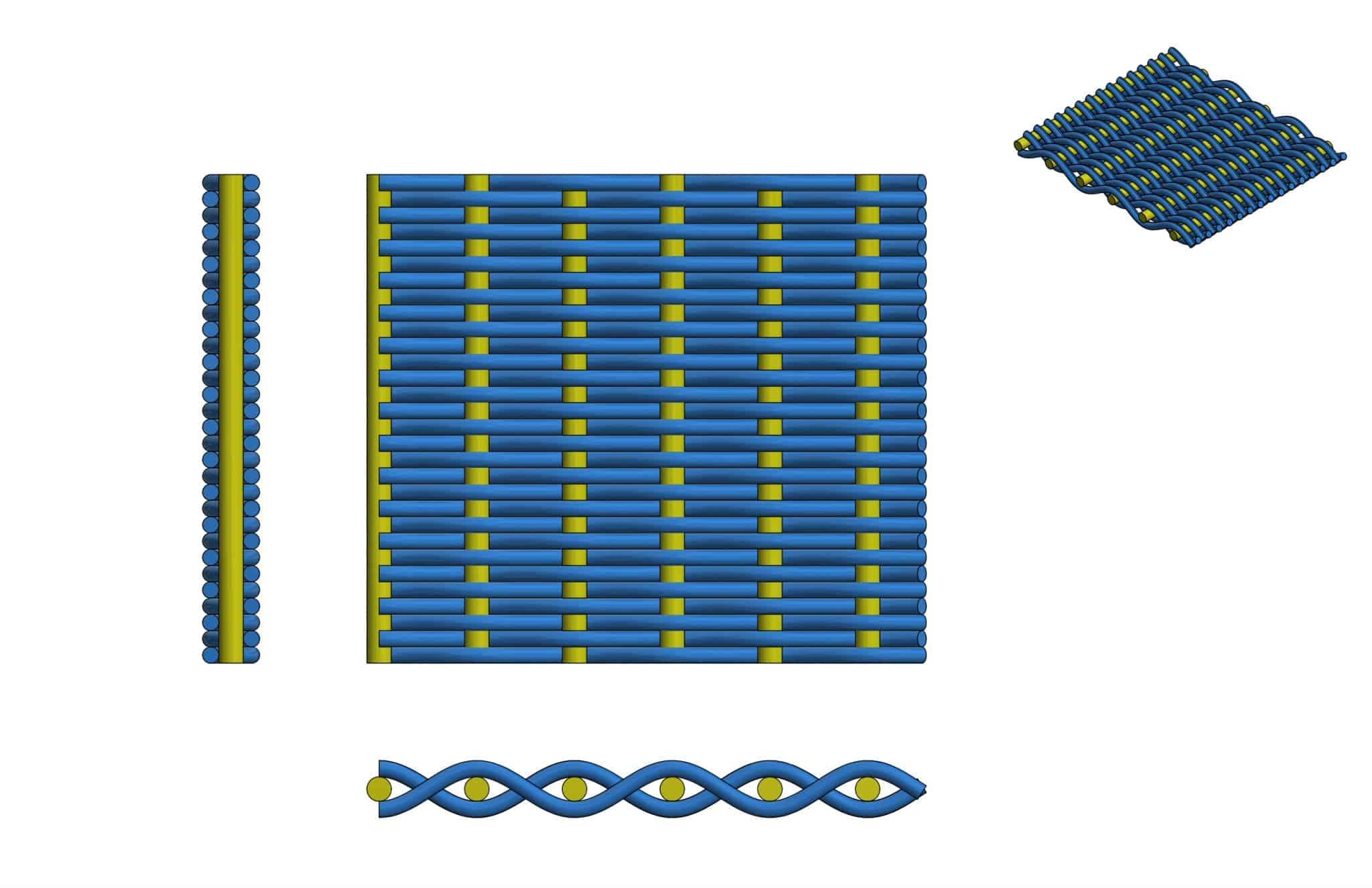

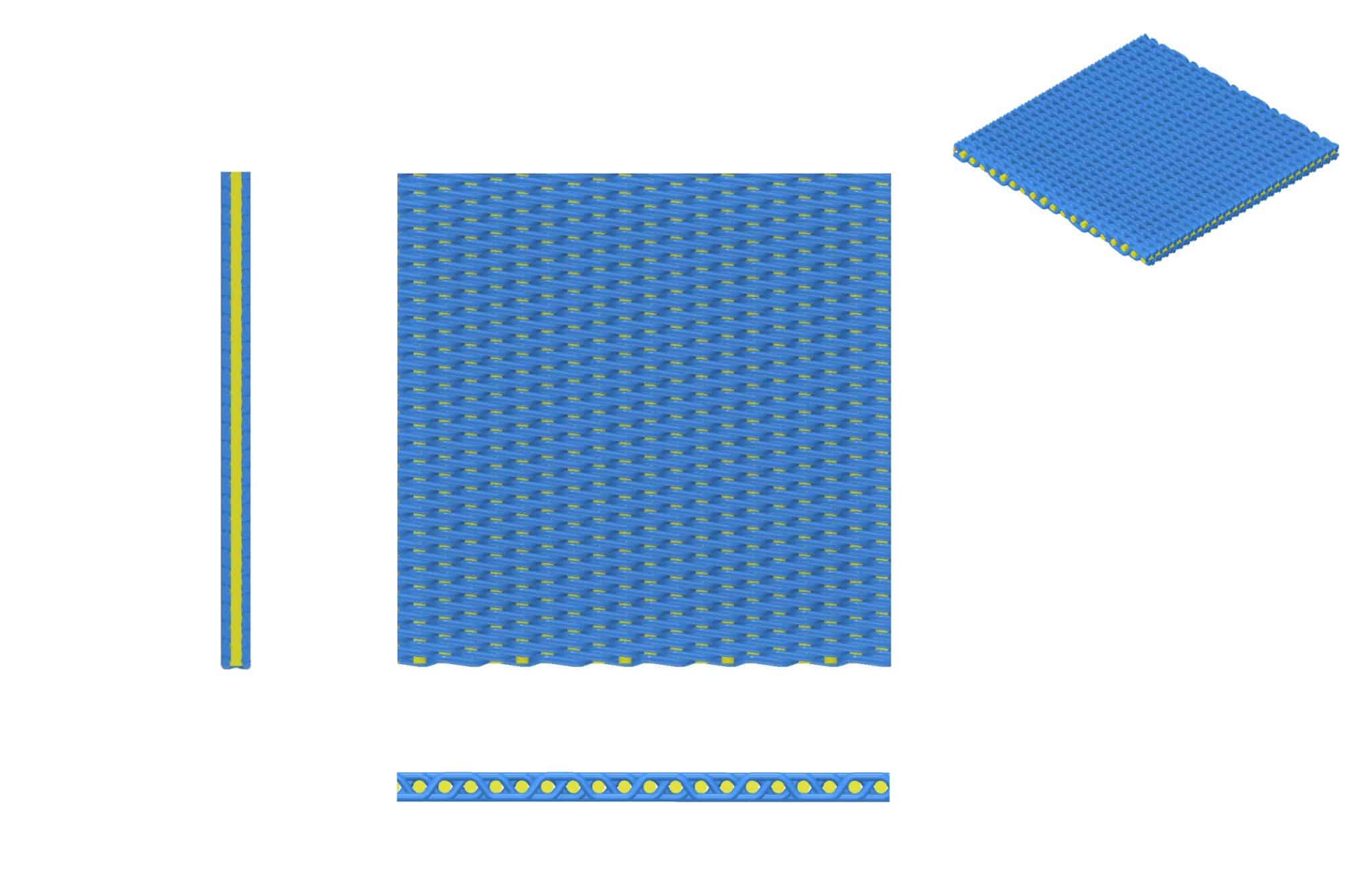

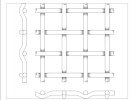

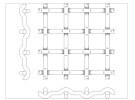

Reverse Dutch Weave & Reverse Dutch Twill Weave Woven Wire Cloth

Reverse Dutch weave woven wire cloth is woven using two sizes of wire. Smaller wires are used in the warp direction and are woven with a larger shute wire. The smaller wires are woven tightly together, providing a tight mesh for filtering. The larger wire provides strength to the mesh. The primary uses of this woven wire cloth are filtration and separation of liquid and slurry products.

Reverse Twill Dutch weave woven wire cloth combines Dutch and twill weaving to provide a fine mesh filtering cloth. The weaving process allows for the use of very fine wires, producing filtering mesh for gas and liquid applications. We also provide Herringbone and Broken Pattern Reverse Twill Dutch Weave Products.

We also offer high tensile warp wire configurations that are commonly used in auto screen changers used in the plastic extrusion industry.

Dorstener Wire Tech offers custom wire configurations for woven wire cloth to meet the specific needs of our clients. For Dutch weaves, micron-grade wire is most commonly used.

In addition, DWT has the capability to manufacture:

- High Tensile Warp wire for Auto-Screen changers used in the Plastic Extrusion Industry.

- Rubbed Edges after slitting to help with tracking for Auto-Screen changers.

- Plasma and laser cut parts to help prevent wire’s edges from fraying.

- 100% Inspection of Wire Cloth for critical applications such as sand screens and aerospace applications.

We offer a wide range of metals and alloys to provide the best material or combination of materials for the filter mesh. Contact us today for more information or a detailed quote.

Laser Cut Woven Wire Cloth Parts

Dorstener Wire Tech also offers state-of-the-art laser cutting allowing your ideas and drawings to become parts in just seconds. DWT’s expert staff can help you generate a drawing based on your ideas or you can send us your CAD drawing and we will gladly bring it to life. This is how we’re able to provide quick turnarounds for prototypes, which can give you an edge over your competition when pursuing your customer’s next purchase order.

Resources

Woven Wire Cloth Brochure

12-page sales brochure for Woven Wire Cloth with standard specifications (PDF)

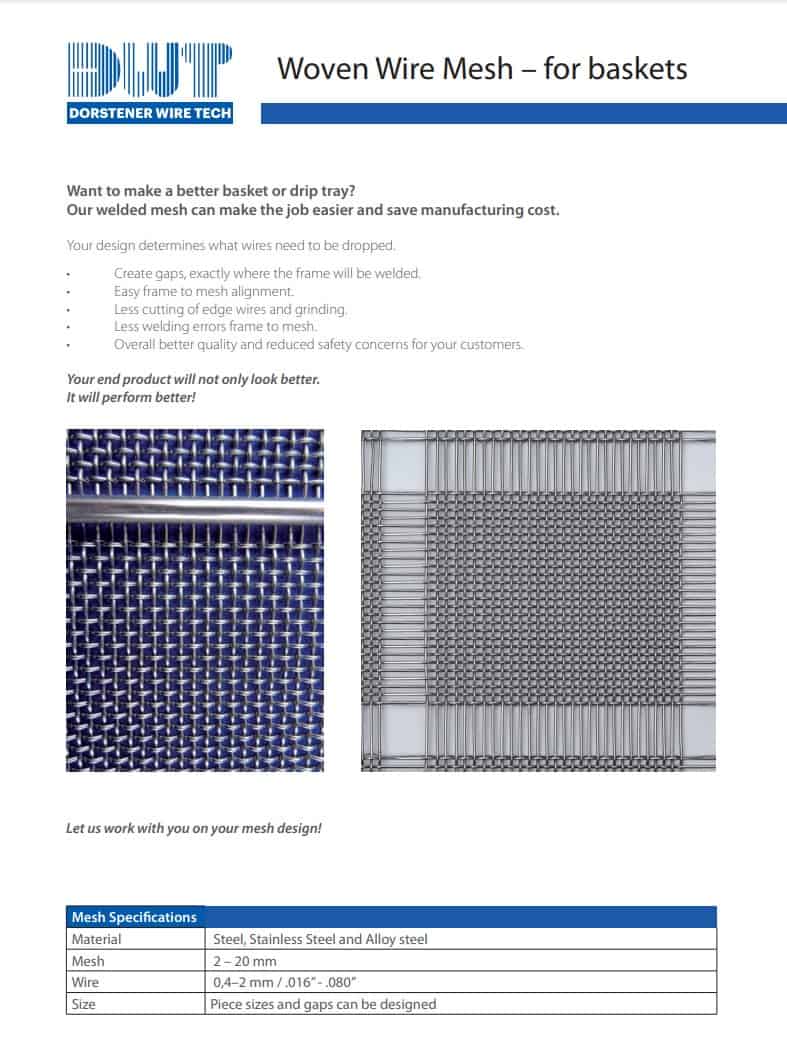

Woven Wire Mesh – for baskets

1-page sales brochure for Woven Wire Cloth for baskets with standard specifications (PDF)

Welded Wire Mesh Solutions

12-page sales brochure for Welded Wire Mesh with standard specifications (PDF)

SPECIFICATIONS FOR COMMON PLAIN AND TWILL WEAVE WIRE CLOTH

4-page specifications for Common Plain and Twill Weave Wire Cloth (PDF)

Specifications Plain Dutch and Twill Dutch Weave Filter Cloth

1-page specifications for Plain Dutch and Twill Dutch Weave Filter Cloth (PDF)

Specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth

1-page specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth (PDF)

Stainless Steel Woven Cloth Materials Chemistry

Stainless Steel Woven Cloth Materials Chemistry (PDF)

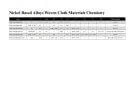

Nickel Based Alloy Woven Cloth Materials Chemistry

Nickel Based Alloy Woven Cloth Materials Chemistry (PDF)

Copper, Brass, & Bronze Woven Cloth Materials Chemistry

Copper, Brass, & Bronze Woven Cloth Materials Chemistry (PDF)

Plain Weave Drawing

Plain Weave drawing (PDF)

Twill Weave Drawing

Twill Weave drawing (PDF)

Plain Dutch Weave Drawing

Plain Dutch Weave Drawing (PDF)

Twill Dutch Weave Drawing

Twill Dutch Weave drawing (PDF)

Flat Top Crimp Drawing

Flat Top Crimp drawing (PDF)

Intermediate Crimp Drawing

Intermediate Crimp drawing (PDF)

Lock Crimp Drawing

Lock Crimp drawing (PDF)

ASTM E2016 Standard Specification for Industrial Woven Wire Cloth

This specification covers industrial woven wire fabric, referred to as wire cloth, for general use including the separation of particles. (purchase)

ASTM E2814 Standard Specification for Industrial Woven Wire Filter Cloth

This specification covers the special grade of industrial woven wire cloth, referred to as filter cloth, for general filtration including the separation of solids from fluids (liquids or gases), based on a desired particle size retention. Filter cloth can be made of any primary metal or metal alloy wire that is suitable for weaving. (purchase)

HAVE QUESTIONS OR NEED A QUOTE?

If you have any questions, need a quote or would like to receive more detailed information on our products and services, please contact us today. We are ready to serve you.

DORSTENER WIRE TECH

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(888) 931-9473 toll free

(281) 651-6226 local

(281) 651-6228 fax