Green Hydrogen Applications

Green hydrogen, which is produced through the electrolysis of water using renewable energy sources, has become increasingly important in the context of the transition to a low-carbon economy. As the world looks to reduce carbon emissions to mitigate the effects of climate change, Dorstener Wire Tech remains committed to providing our customers with the best possible materials solutions to help them achieve their sustainability goals.

As the world continues to transition towards cleaner energy sources, green hydrogen has emerged as a promising alternative to fossil fuels. Electrolysis of water using renewable energy is the most common method of producing green hydrogen. However, the efficient production of green hydrogen requires the use of specialized materials that can enhance the performance of the electrolysis cells, gas diffusion layers, and hydrogen separation membranes. Dorstener Wire Tech offers a range of materials that can improve the efficiency and performance of these processes.

Green Hydrogen Wire Cloth for Electrolysis Cells

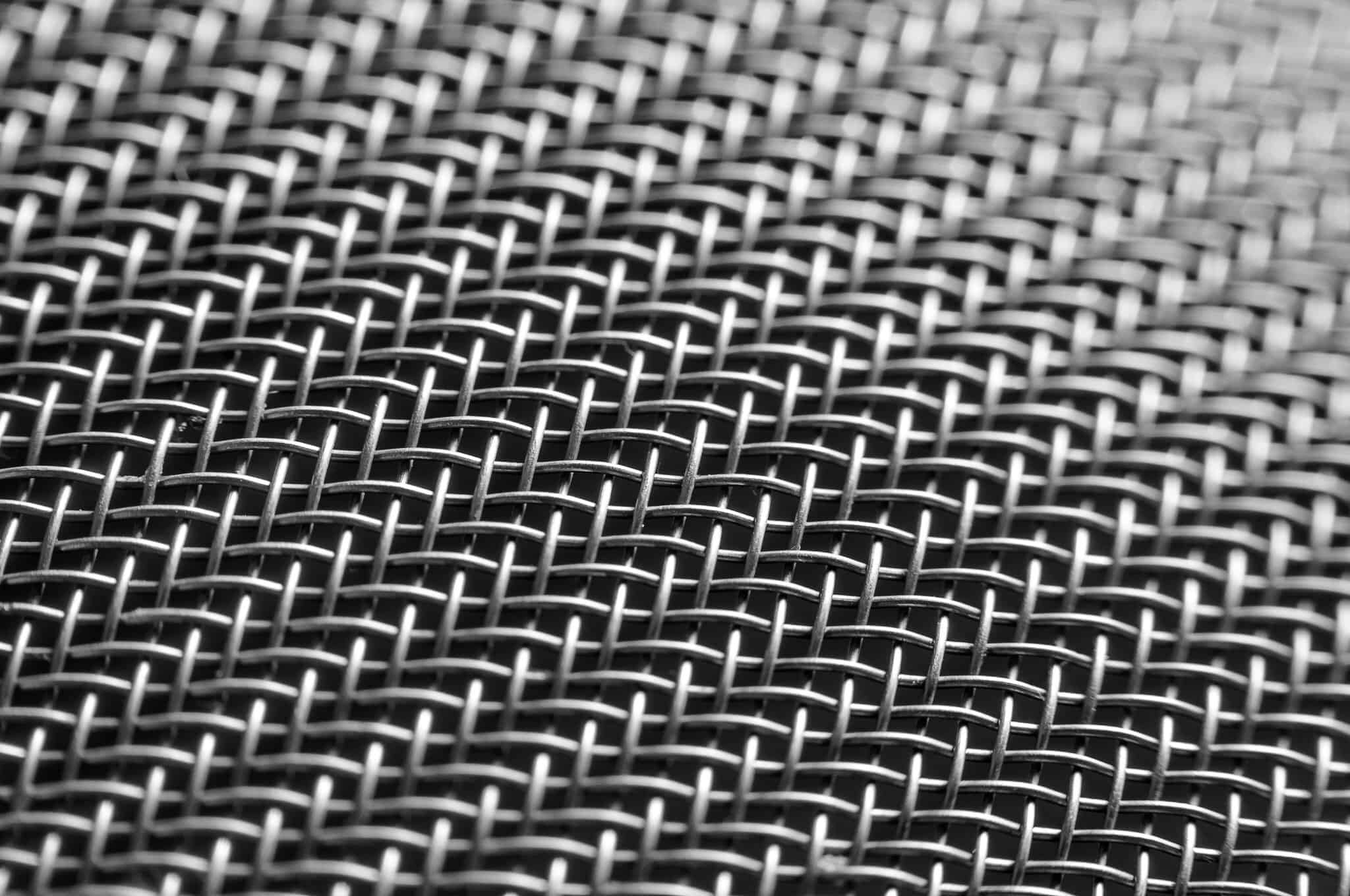

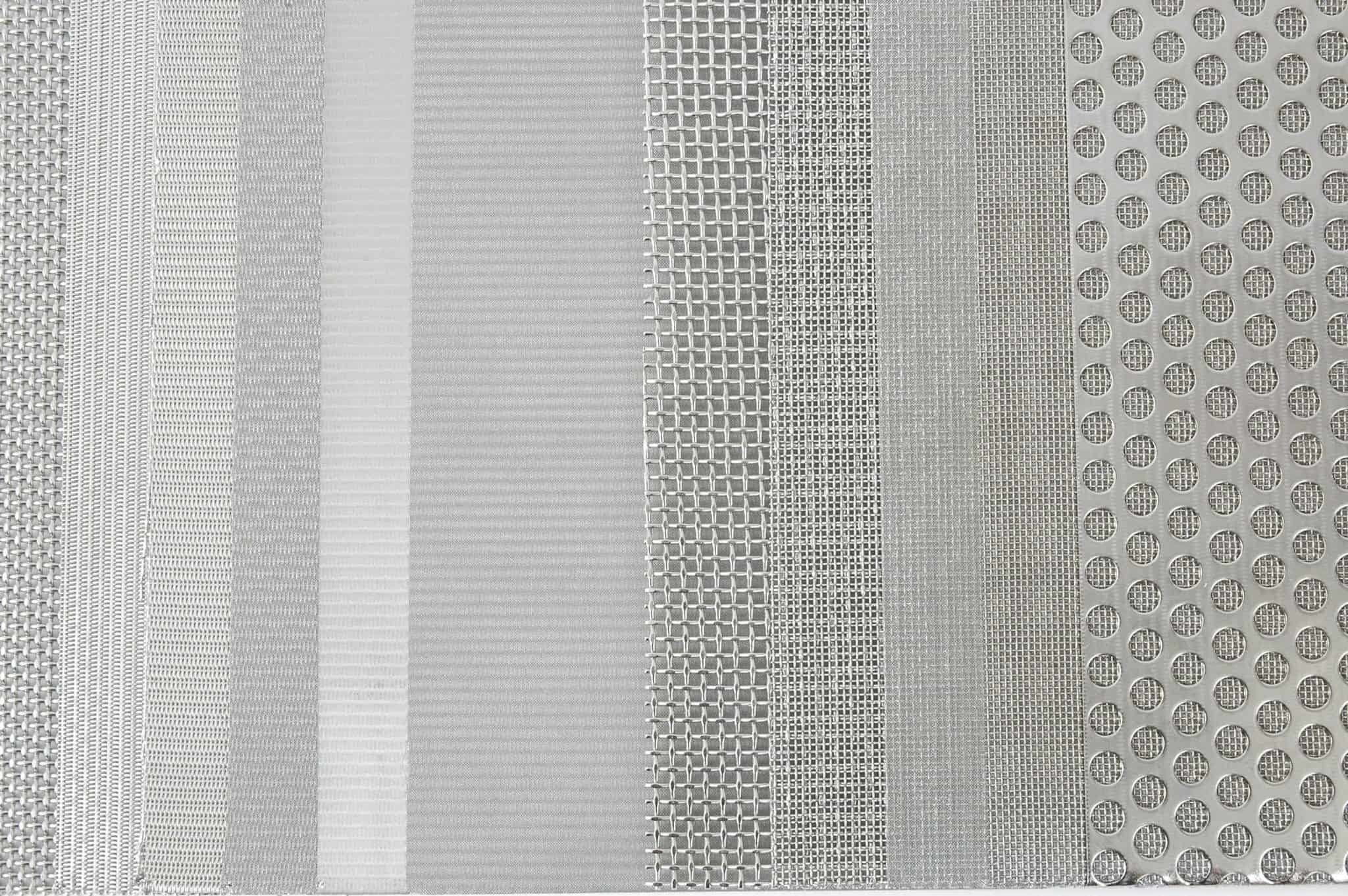

Dorstener Wire Tech’s wire cloth mesh is commonly used in the construction of electrolysis cells as a support structure for the electrodes. The high-strength and good electrical conductivity of the mesh provides structural integrity to the cells while improving electrode performance and overall efficiency. The wire cloth mesh is available in a range of materials and configurations, including plain weave, twill weave, and Dutch weave, allowing for customized solutions to meet specific requirements.

Sintered Porous Metal Plates for Gas Diffusion Layers

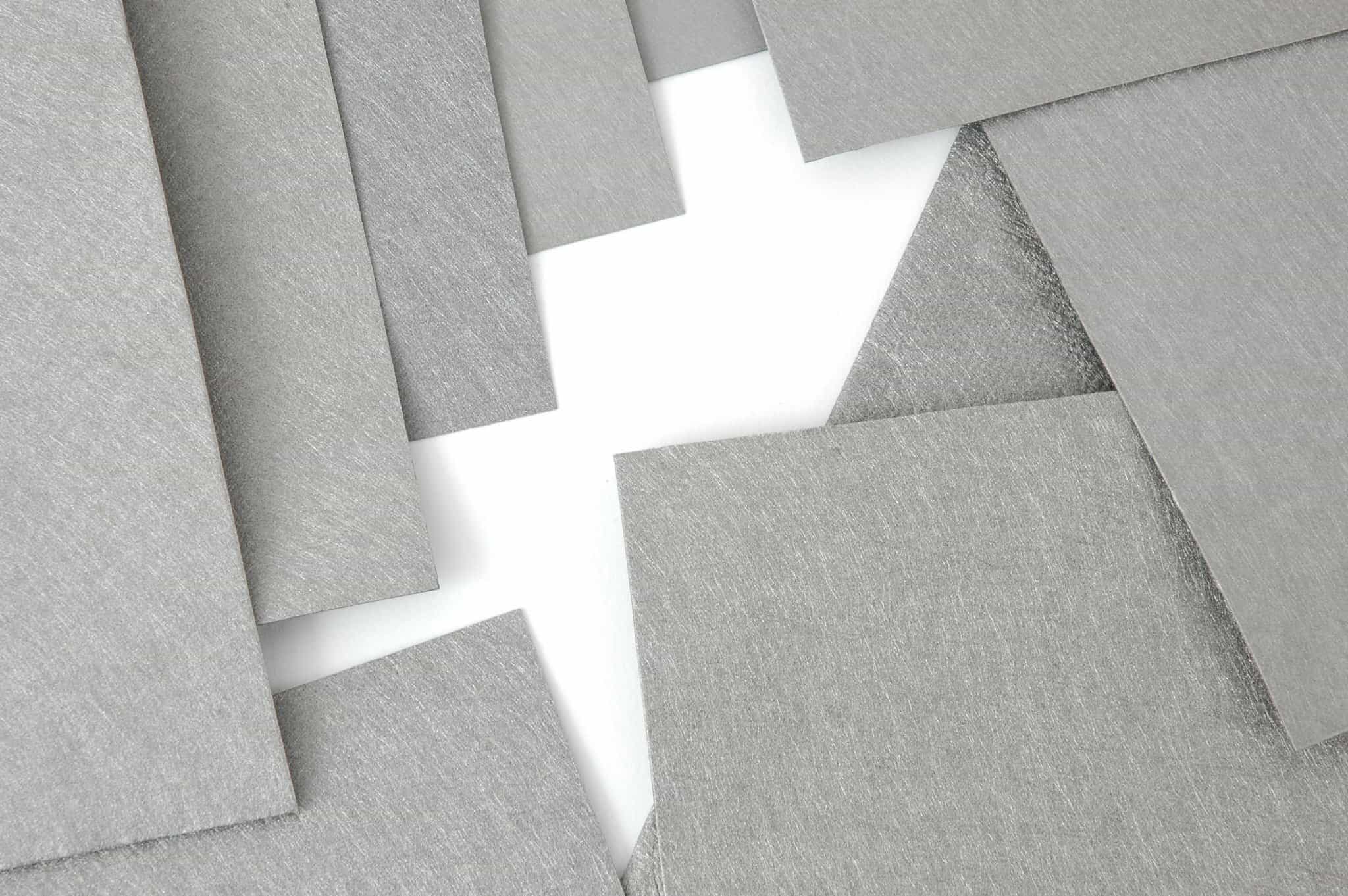

Gas diffusion layers (GDLs) are critical components of proton exchange membrane (PEM) fuel cells, facilitating the transfer of reactants and products to and from the electrodes. Dorstener Wire Tech’s sintered wire cloth and sintered fiber felt materials can be used to create highly porous GDLs, improving gas and liquid transport and increasing the efficiency of the fuel cell. The sintered laminate material is made up of layers of woven wire mesh, perforated plate, while the fiber felt is produced from metallic fibers that are non-woven and then sintered.

Sintered Porous Metal Structure for Hydrogen Separation Membranes

The separation of hydrogen from other gases, such as carbon dioxide or nitrogen, is essential in the production of high-purity hydrogen gas. Dorstener Wire Tech’s wire cloth mesh can be used as a support structure for the membrane material, as well as to enhance the membrane’s permeability and selectivity. The company’s expertise in the development of specialized materials allows for customized solutions to meet specific hydrogen separation requirements.

Here are some potential benefits of diffusion bonded woven wire mesh laminate materials for green hydrogen production:

- Porous plate with ULTRA SMOOTH SURFACE for high pressure membrane Support.

- High durability and corrosion resistance: Diffusion bonded woven wire mesh laminate materials can withstand harsh conditions, such as high temperatures, high pressure, and corrosive environments, without degradation or failure.

- High efficiency and performance: The uniform pore size and distribution of woven wire mesh laminates allow for efficient and effective mass transfer, which can improve the overall performance of the hydrogen production process.

- Scalability: Diffusion bonded woven wire mesh laminates can be easily scaled up or down to meet production demands, making them a versatile and adaptable option for hydrogen production.

- Multilayer diffusion bonded structures can be designed with choices of woven wire meshes, fiber felts and other metallic components which offer uniform distribution of flow.

As a premier provider of advanced materials for the hydrogen production industry, we are dedicated to delivering superior solutions that enable optimal performance and efficiency. Our extensive product portfolio includes woven wire mesh, fiber felt, and diffusion-bonded mesh laminate, among other cutting-edge materials that are widely recognized for their exceptional quality and reliability.

With a firm commitment to customer satisfaction, our team of highly skilled professionals is always available to provide unparalleled technical support and assistance, ensuring that our clients receive the most effective solutions for their unique requirements.

We would welcome the opportunity to discuss our products and services with you in greater detail, and to explore how our innovative solutions can help you achieve your goals and objectives.

Resources

Woven Wire Cloth Brochure

12-page sales brochure for Woven Wire Cloth with standard specifications (PDF)

Welded Wire Mesh Solutions

12-page sales brochure for Welded Wire Mesh with standard specifications (PDF)

SPECIFICATIONS FOR COMMON PLAIN AND TWILL WEAVE WIRE CLOTH

4-page specifications for Common Plain and Twill Weave Wire Cloth (PDF)

Specifications Plain Dutch and Twill Dutch Weave Filter Cloth

1-page specifications for Plain Dutch and Twill Dutch Weave Filter Cloth (PDF)

Specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth

1-page specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth (PDF)

Stainless Steel Woven Cloth Materials Chemistry

Stainless Steel Woven Cloth Materials Chemistry (PDF)

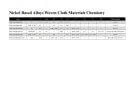

Nickel Based Alloy Woven Cloth Materials Chemistry

Nickel Based Alloy Woven Cloth Materials Chemistry (PDF)

Copper, Brass, & Bronze Woven Cloth Materials Chemistry

Copper, Brass, & Bronze Woven Cloth Materials Chemistry (PDF)

ASTM E2016 Standard Specification for Industrial Woven Wire Cloth

This specification covers industrial woven wire fabric, referred to as wire cloth, for general use including the separation of particles. (purchase)

ASTM E2814 Standard Specification for Industrial Woven Wire Filter Cloth

This specification covers the special grade of industrial woven wire cloth, referred to as filter cloth, for general filtration including the separation of solids from fluids (liquids or gases), based on a desired particle size retention. Filter cloth can be made of any primary metal or metal alloy wire that is suitable for weaving. (purchase)

HAVE QUESTIONS OR NEED A QUOTE?

If you have any questions, need a quote or would like to receive more detailed information on our products and services, please contact us today. We are ready to serve you.

DORSTENER WIRE TECH

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(888) 931-9473 toll free

(281) 651-6226 local

(281) 651-6228 fax