Industrial Filtration Applications for Wire Mesh & Wire Cloth

Industrial Filtration Products

Metal wire cloth and wire mesh industrial filtration are frequently used in commercial and industrial/OEM applications for good reasons. In some industrial filtration applications the goal is to protect downstream components from particulate matter. In other cases, a metal wire cloth filter can be used to separate, or screen one substance from another.

Whether your specific industrial filtration application calls for removing unwanted contaminants from fluid or air, protecting expensive process equipment, or simply separating one material from another, Dorstener Wire Tech can manufacture a custom metal wire cloth industrial filter for your exact specifications. Bag filters, cartridge filters and dust filters are typically made with a synthetic media. Dorstener Wire Tech can create your exact dimension filter and substitute a stainless steel wire cloth or wire mesh media which can allow for better flow and more efficient machine functionality. Custom fabricated metal wire cloth and wire mesh filters can deliver the perfect size dimensions and performance characteristics desired.

- Dorstener Wire Tech can manufacture industrial filter components to match any OEM specifications.

- Dorstener Wire Tech filters are superior because they can be cleaned and re-used. Stainless steel wire cloth and wire mesh media eliminates shedding issues that are commonly associated with paper or felt media.

- Dorstener Wire Tech can produce y-strainer filters, industrial bag house filters, hydraulic filters, coalescing filter elements, and liquid and natural gas filter elements.

Custom Industrial Filters Work Better

Our custom metal wire cloth and wire mesh filters and strainers keep your business running. Whether you’re looking for a more durable or less expensive OEM alternative, or you have a true custom challenge due to an outdated part or unique challenge, we can handle it.

We can make custom replacement wire cloth and wire mesh industrial filters that meet or exceed original OEM specifications. We can work off of your drawings or even build a new part using a worn or damaged out-of-production product as a template.

Metal wire cloth and wire mesh filtering applications vary greatly, so we offer a broad range of shapes, closures, end styles and materials including stainless steel, nickel based alloy, copper, brass and bronze. It has made us the proven provider of choice for many applications.

Industrial Filtration Applications for Wire Mesh & Wire Cloth

Here are some examples of the industrial filtration applications that Dorstener metal wire cloth and wire mesh is used for:

Some specialty industrial filtration we offer:

Catalyst Support Screens

Dorstener Wire Tech produces a wide range of catalyst support screens and grids for the petrochemical and refining industries. Wire mesh support screens allow for more open area and more precise openings than perforated steel or wedge wire screens. As a result, catalyst support screens manufactured using wire mesh are more efficient.

Micro Mesh Parts

Dorstener Wire Tech manufactures custom miniature mesh parts that are used in miniature valves, condensers, and electronic assemblies. We specialize in the design and manufacture of custom wire cloth and mesh, and offer fabrication, stamping and finishing services to provide production-ready miniature wire cloth elements. Soft sintered, annealed and diffusion bonded cloth are available for applications that require precise shaping, flexibility during processing and part stability.

Sand Screens and Filter Elements

DWT has supplied wire cloth and drainage screen products for the oil and gas industry for more than 15 years. Today we offer a wide range of filtration and drainage screen cartridges. Our traceability and quality system insures you receive the proper documentation with your wire sand screens, sand screen mesh, and custom wire mesh filtration products each and every order.

Hot Gas Filtration Elements

Dorstener Wire Tech produces a wide range of woven wire mesh and welded wire products ideally suited for hot gas filtration applications.

Just like their fossil fuel cousins, alternative fuels need filtration. Many of these fuels require high temperature processing, resulting in the necessity for special metals, media, and finishing to handle the harsh processing environment. DWT has the expertise and products to manufacture wire filtering products for this new demanding market.

Common applications in this new market include wire cloth filter elements for biofuel processing and power generation, spark arresting screens, catalyst recovery media, heat diffusers, and cleaning filters for gases released during chemical processing.

Extruder Screens

High quality filtration requires high quality media. Polymer manufacturing requires a wide range of filters and filter media for processing, finishing and recycling the materials. Dorstener Wire Tech has over 15 years experience in manufacturing and engineering of polymer filtration components of many varieties to meet the challenges faced by today’s polymer processing Industry. Dorstener Wire Tech is a fully integrated company that not only produces polymer filters and extruder screens, we produce the media we use in our filters. All of our polymer filtration media is designed for the specific requirements of the users processes. Our state of the art manufacturing facilities allow us to offer high performance filters direct from the manufacturer at an economical cost.

Polymer Filtration

The plastics and polymer industry requires many different filters to insure a clean melt stream. Our metal filter screens are engineered to fit all styles and types of melt pumps and screen changers. The end goal of our product is to insure the final quality of your product.

The most common screen changers for melt filtration use single or multilayer wire cloth extruder screens. We produce these in round discs, rectangular or kidney shaped screens. The construction of the screen pack is critical to process performance and final product quality. Mesh combinations are carefullt chosen to achieve a high strength pack that provides desired filtration levels and optimal throughput. To assist in the production of sensitive or high value polymers we offer frame pack screens for superior sealing and control.

Stainless Steel Air Filtration

Dorstener Wire Tech can supply air filtration and cooling tower panels with a newly designed filter media. Stainless steel wire mesh in the air filtration industry is not only found in the hot gas sector. It can be used for the filtration of pollen, fibers, insects and other impurities upstream of air-cooled units, we have introduced our air sieve as a protective filter to the market.

Fine cloths with a large air-flow, reinforced by our sandwich construction, allow a great, robust filtration surface that is corrosion-resistant and can be cleaned easily.

Extruder Screens for Food Contact Polymer Filtration

Are you producing food contact polymer for beverage containers, produce packaging for food contact film? Since food grade materials must adhere to a variety of regulatory requirements, your filtration parameters and expectations should be just as stringent. Dorstener Wire Tech can engineer a filtration component that will ensure all of your concerns are eased.

Dorstener Wire Tech can ensure that your parts are ultrasonic cleaned to provide a peace of mind that your food contact materials are being filtered through filter media that is free of dirt, oil and grease. Ultrasonic cleaning is available for all parts in stainless steel and carbon steel alloys.

Dorstener is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the industrial filtration wire product that will meet your design requirements and budget. Contact us today for more information about our wire cloth and welded wire mesh used in industrial filtration applications.

Resources

Woven Wire Cloth Brochure

12-page sales brochure for Woven Wire Cloth with standard specifications (PDF)

Welded Wire Mesh Solutions

12-page sales brochure for Welded Wire Mesh with standard specifications (PDF)

SPECIFICATIONS FOR COMMON PLAIN AND TWILL WEAVE WIRE CLOTH

4-page specifications for Common Plain and Twill Weave Wire Cloth (PDF)

Filtration Catalog

8-page catalog for Filtration (PDF)

Specifications Plain Dutch and Twill Dutch Weave Filter Cloth

1-page specifications for Plain Dutch and Twill Dutch Weave Filter Cloth (PDF)

Specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth

1-page specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth (PDF)

Stainless Steel Woven Cloth Materials Chemistry

Stainless Steel Woven Cloth Materials Chemistry (PDF)

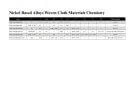

Nickel Based Alloy Woven Cloth Materials Chemistry

Nickel Based Alloy Woven Cloth Materials Chemistry (PDF)

Copper, Brass, & Bronze Woven Cloth Materials Chemistry

Copper, Brass, & Bronze Woven Cloth Materials Chemistry (PDF)

ASTM E2016 Standard Specification for Industrial Woven Wire Cloth

This specification covers industrial woven wire fabric, referred to as wire cloth, for general use including the separation of particles. (purchase)

ASTM E2814 Standard Specification for Industrial Woven Wire Filter Cloth

This specification covers the special grade of industrial woven wire cloth, referred to as filter cloth, for general filtration including the separation of solids from fluids (liquids or gases), based on a desired particle size retention. Filter cloth can be made of any primary metal or metal alloy wire that is suitable for weaving. (purchase)

HAVE QUESTIONS OR NEED A QUOTE?

If you have any questions, need a quote or would like to receive more detailed information on our products and services, please contact us today. We are ready to serve you.