Straining Applications for Wire Cloth

In straining applications, a strainer is used to “strain” or “filter” contaminates in a system that could flow down the line and damage more expensive pieces of equipment, or spoil a manufacturing process. In effect, a strainer could be viewed as a very inexpensive “insurance policy” to help protect the overall systems.

The most important part of the strainer or filter is the screen because it is the screen that guards an orifice or protects moving parts. One particle of scale, dirt, or other entrainment can cause serious damage to highly engineered, expensive equipment. To prevent equipment damage and protect against contamination, strainer screens must be designed of durable, corrosion-resistant materials with the specific application in mind.

Woven Wire Straining Applications

Woven wire is the most popular material used in the manufacture of modern strainer screens. This is partly due to its inherent characteristics — high percentage of open area and roundness — which favor high flow and are ideal for flow pattern. Other reasons for woven wire popularity in straining applications include its high strength and its ability to withstand extreme temperature variations, corrosive environments and vibration.

Woven screens find their greatest use in low and medium pressure applications. In high pressure service, the fine mesh screen may be supported by a coarse backing screen.

Straining Applications Meshes and Weaves

Plain weave screens ranging from .0008″ openings upward represent the bulk of strainer applications. For high pressures or heavy loads, twilled weaves or corduroy type weaves are available.

Filter screening, using aids, usually range from 60 to 100 mesh screens. In this service, twilled weaves or corduroy cloths are usually recommended.

Straining Applications Strainer Shapes

Basket strainers are designed and constructed to strain particulates out of high-volume process streams or processes with heavy soil loads, helping manufacturers increase productivity and protect product integrity.

Y-Strainers are devices for mechanically removing unwanted solids from liquid, gas or steam lines by means of a wire mesh straining element. They are used in pipelines to protect pumps, meters, control valves, steam traps, regulators and other process equipment. Y-Strainers are used in a wide variety of liquid straining applications to protect downstream process system components in many industries, including: chemical processing, petroleum, power generation and marine. Water handling applications, where Y-Strainers are used to protect equipment that could be damaged or clogged by unwanted sand, gravel or other debris, are very common.

Dorstener Wire Tech produces a wide range of wire cloth for straining applications. DWT offers solutions for corrosion resistance, high flow, high strength, and easy to clean straining applications.

Food and Beverage Strainers

Resources

Woven Wire Cloth Brochure

12-page sales brochure for Woven Wire Cloth with standard specifications (PDF)

Welded Wire Mesh Solutions

12-page sales brochure for Welded Wire Mesh with standard specifications (PDF)

SPECIFICATIONS FOR COMMON PLAIN AND TWILL WEAVE WIRE CLOTH

4-page specifications for Common Plain and Twill Weave Wire Cloth (PDF)

Specifications Plain Dutch and Twill Dutch Weave Filter Cloth

1-page specifications for Plain Dutch and Twill Dutch Weave Filter Cloth (PDF)

Specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth

1-page specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth (PDF)

Stainless Steel Woven Cloth Materials Chemistry

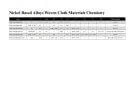

Nickel Based Alloy Woven Cloth Materials Chemistry

Copper, Brass, & Bronze Woven Cloth Materials Chemistry

ASTM E2016 Standard Specification for Industrial Woven Wire Cloth

This specification covers industrial woven wire fabric, referred to as wire cloth, for general use including the separation of particles. (purchase)

ASTM E2814 Standard Specification for Industrial Woven Wire Filter Cloth

This specification covers the special grade of industrial woven wire cloth, referred to as filter cloth, for general filtration including the separation of solids from fluids (liquids or gases), based on a desired particle size retention. Filter cloth can be made of any primary metal or metal alloy wire that is suitable for weaving. (purchase)

HAVE QUESTIONS OR NEED A QUOTE?

If you have any questions, need a quote or would like to receive more detailed information on our products and services, please contact us today. We are ready to serve you.

DORSTENER WIRE TECH

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(888) 931-9473 toll free

(281) 651-6226 local

(281) 651-6228 fax