Stainless Steel Mesh, Cloth & Screen

Available Materials & Alloys

Dorstener Wire offers a large selection of alloys for our stainless steel mesh and woven wire cloth products. Our staff will work with you to determine the appropriate material or materials to use for your application. In addition, DWT offers alloy verification services to test the selection of woven wire cloth mesh alloys and determine the correct alloy to use.

Standard alloys for woven wire cloth include:

- Stainless steel mesh and nickel based alloys for high temperature & corrosive applications

- Specialty coated products, including Teflon® and epoxy-coated stainless steel for chemical and petrochemical applications

- Brass and bronze alloys for corrosive applications

- Copper alloys for specialty applications requiring electrical conductivity

- Exotic and high temp alloys (Monel®, Inconel®, Alloy 20) for corrosive high temperature applications

- Carbon steel and specialty coated alloys for high impact and specialty applications requiring coating or other finishing.

Questions? Feel free to contact us to learn more about our woven cloth alloys and verification services.

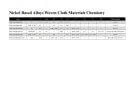

The table below shows the various alloys available from Dorstener Wire Tech.

Stainless Steel Mesh, Cloth, & Screen

Dorstener Wire offers a wide variety of stainless steel mesh, cloth, and screen. The stainless steel mesh and cloth material grades include: 302 SS, 304 SS, 304L SS, 310 SS, 316 SS, 316L SS, 317L SS, 321 SS, 330 SS, 347 SS, 410 SS, and 430 SS. Stainless steel mesh alloys are most applicable for corrosive and high temperature applications.

302 Stainless Steel Mesh

302 Stainless Steel Mesh is a low grade stainless steel alloy. It is a very economical cost and it is produced in China and other countries as a standard stainless grade.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.15 |

| 2 | Manganese | 2 |

| 3 | Phosphorous | 0.045 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 17.00-19.00 |

| 7 | Nickel | 8.00-10.00 |

| 8 | Molybdenum | * |

| 9 | Other Elements | * |

304 Stainless Steel Mesh

304 Stainless Steel Mesh is the most common stainless alloy used in wire weaving. Excellent corrosion properties and can withstand temperatures of 1100 Degrees F.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.08 |

| 2 | Manganese | 2 |

| 3 | Phosphorous | 0.045 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 18.00-20.00 |

| 7 | Nickel | 8.00-10.50 |

| 8 | Molybdenum | * |

| 9 | Other Elements | * |

304L Stainless Steel Mesh

304L Stainless Steel Mesh has similar properties as 304ss but lower carbon content to permit better welding.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.03 |

| 2 | Manganese | 2 |

| 3 | Phosphorous | 0.045 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 17.00-19.00 |

| 7 | Nickel | 8.00-10.00 |

| 8 | Molybdenum | * |

| 9 | Other Elements | * |

310 Stainless Steel Mesh

310 Stainless Steel Mesh is a high temperature nickel alloy that has excellent corrosion properties. It can withstand high operating temperatures up to 1800 degrees F for extended time periods.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.25 |

| 2 | Manganese | 2 |

| 3 | Phosphorous | 0.045 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 24.00-26.00 |

| 7 | Nickel | 19.00-22.00 |

| 8 | Molybdenum | * |

| 9 | Other Elements | * |

316 Stainless Steel Mesh

316 Stainless Steel Mesh has similar properties to 304ss but is stabilized by the addition of Molybdenum for increased resistance to chemical corrosion.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.08 |

| 2 | Manganese | 2 |

| 3 | Phosphorous | 0.045 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 16.00-18.00 |

| 7 | Nickel | 10.00-14.00 |

| 8 | Molybdenum | 2.0000-3.0000 |

| 9 | Other Elements | * |

316L Stainless Steel Mesh

316L Stainless Steel Mesh has similar properties as 316 SS but lower carbon content to permit better welding.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.03 |

| 2 | Manganese | 2 |

| 3 | Phosphorous | 0.045 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 16.00-18.00 |

| 7 | Nickel | 10.00-14.00 |

| 8 | Molybdenum | 2.0000-3.0000 |

| 9 | Other Elements | * |

317L Stainless Steel Mesh

317L Stainless Steel Mesh has increased corrosion resistance compared to 316ss. Its L grade allows better welding.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.03 |

| 2 | Manganese | 2 |

| 3 | Phosphorous | 0.045 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 18.00-20.00 |

| 7 | Nickel | 11.00-15.00 |

| 8 | Molybdenum | 3.000-4.000 |

| 9 | Other Elements | * |

321 Stainless Steel Mesh

Similar to 347 Stainless Steel Mesh and can handle high operating temperatures. Has the addition of Titanium.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.08 |

| 2 | Manganese | 2 |

| 3 | Phosphorous | 0.045 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 17.00-19.00 |

| 7 | Nickel | 9.00-12.00 |

| 8 | Molybdenum | * |

| 9 | Other Elements | TI 5XC MIN |

330 Stainless Steel Mesh

330 Stainless Steel Mesh is an alloy that can handle operating temperatures up to 1650 Degrees F. Common applications for 330 SS includes heat treating fixtures & baskets.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.08 |

| 2 | Manganese | 2 |

| 3 | Phosphorous | 0.03 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | .750-1.500 |

| 6 | Chromium | 17.00-20.00 |

| 7 | Nickel | 34.00-37.00 |

| 8 | Molybdenum | * |

| 9 | Other Elements | TI 5XC MIN |

347Stainless Steel Mesh

347 Stainless Steel Mesh has similar properties of 304 SS but has the additions of Columbium for stability in high operation temperatures.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.08 |

| 2 | Manganese | 2 |

| 3 | Phosphorous | 0.045 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 17.00-19.00 |

| 7 | Nickel | 9.00-13.00 |

| 8 | Molybdenum | * |

| 9 | Other Elements | CB + TA 10XC MIN |

410 Stainless Steel Mesh

410 Stainless Steel Mesh has very good resistance to corrosion & oxidation.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.15 |

| 2 | Manganese | 1 |

| 3 | Phosphorous | 0.04 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 11.50-13.50 |

| 7 | Nickel | * |

| 8 | Molybdenum | * |

| 9 | Other Elements | * |

430 Stainless Steel Mesh

430 Stainless Steel Mesh has magnetic properties similar to carbon steel but with much higher corrosion resistance. It is commonly used in the food processing industry.

| wdt_ID | Element | Value |

|---|---|---|

| 1 | Carbon | 0.12 |

| 2 | Manganese | 1 |

| 3 | Phosphorous | 0.04 |

| 4 | Sulfur | 0.03 |

| 5 | Silicon | 1 |

| 6 | Chromium | 16.00-18.00 |

| 7 | Nickel | * |

| 8 | Molybdenum | * |

| 9 | Other Elements | * |

Carbon Steel & Specialty Coated Wire Mesh Wire Cloth & Screen

Dorstener Wire Tech offers the following carbon steel and specialty coated wire mesh wire cloth products to fit your application.

Low Carbon Steel Wire Mesh Wire Cloth

Low Carbon steel (C1008) is frequently used in the manufacture of industrial woven and welded wire mesh products due to its low cost and ease of workability. This material has a low resistance to abrasion, chemical attack and corrosion. This material is available in bright and black annealed. Our bright annealed material is much cleaner than standard commodity black steel.

Galvanized Carbon Steel Wire Mesh Wire Cloth

Galvanized or Zinc coated steel offer superior corrosion resistance compared to standard carbon steel without the expense of stainless steel mesh. GAW (Galvanized After Welded/Woven) and GBW (Galvanized Before Welded/Woven) are common terms in the industry. There are various methods of galvanizing. Two of the most common are electro galvanized wire (prior to weaving/welding) and hot dipped galvanized mesh (post weaving/welding).

Copper Flashed / Copper Coated Carbon Steel Wire Mesh Wire Cloth

Copper Flashed steel provides some protection from corrosion and is also used to provide a stable wire for post processing such as nickel or chrome plating.

High Carbon Steel Wire Mesh Wire Cloth

High Carbon steel is primarily used when resistance to abrasion and impact is required. This material is commonly used in sizing of aggregate materials.

Painted and Epoxy Coated Steel Wire Mesh Wire Cloth

We also offer custom applications of specialty paints and epoxy coatings. Epoxy coatings normally add stability to light wire diameter mesh products such as filter support and window screen.

Nickel Based Alloys Woven Wire Cloth

Dorstener Wire offers a wide variety of nickel based alloys woven wire cloth. The nickel based alloys material grades include: Nickel 200, Monel 400, Inconel 600, and Incoloy 800. Nickel based alloys are best used for corrosive and high temperature applications.

Nickel 200

Used in applications where high corrosion properties are required. Some applications could include several chemicals, caustics, and certain organic acids.

Monel 400

One of the most widely used alloys for high corrosion resistance. Used in many food and chemical processes. Monel is a registered trade mark for International Nickel Co INCO.

Inconel 600

High Temp Ally. Common applications for this alloy are heat treating baskets and fixtures. Similar to 330ss. Operates in temperatures in excess of 1650 Degrees F. Incoloy is a registered trademark for International Nickel Co INCO.

Incoloy 800

High Temp Ally. Common applications for this alloy are heat treating baskets and fixtures. Similar to 330ss. Operates in temperatures in excess of 1650 Degrees F. Incoloy is a registered trademark for International Nickel Co INCO.

Copper, Brass, & Bronze Wire Cloth

Dorstener Wire Tech offers the following inventory of copper, brass, and bronze wire cloth for your specific application.

Commercial Bronze Wire Cloth

Commercial Bronze Wire Cloth has a high percent of copper. It is normally used in a corrosion application where brass is not suitable.

Phosphorus Bronze Wire Cloth

Due to its physical properties phosphorous bronze wire cloth is ideal for weaving. It has a wide range of applications including filtration, to screening. Phosphorous Bronze Wire Cloth is stronger than brass and can withstand a great deal of cold working.

Brass Wire Cloth

This is a non-rusting material and is used in some industrial and architectural applications. Click here for material chemistry. This alloy is known for its ability to conduct electricity and is used in applications where electrical properties are needed.

Exotic & High Temp Alloys Wire Cloth

- Alloy 20

- Super Duplex Alloys

- Titanium

- Gold

- Silver

- Platinum

- Tungsten

- Tantalum

- Haynes 25

- Hastelloy B

- Hastelloy C

- Hastelloy X

- Kanthal

- Waspalloy

- 310 Stainless Steel

Specialty Alloy Welded Wire Mesh

Dorstener Wire Tech offers a full line of specialty alloy welded wire mesh products for applications ranging from simple baskets to turbine inlet screens. Our expert staff is available to assist you in selecting the most effective specialty alloy for your welded wire mesh product.

- Monel™

- Alloy 20

- Inconel™

- Nickel-based alloys

- High temp alloys

Other alloys as well as stainless steel wire mesh are available for custom applications. DWT offers alloy verification services to determine whether the alloy selected meets your requirements.

All products can be manufactured using DFAR and non-DFAR compliant materials.

Specialty Alloy Welded Wire Mesh Configurations

DWT’s welded mesh products are offered with the following configurations:

- Opening size, or mesh count, ranging from .030”-2”. Typically the openings of welded mesh are measured from center to center of the wire.

- Wire diameters ranging from .020” to .080” in standard configurations. Larger diameter wires are available for custom applications. Wire diameters are measured prior to welding.

- Roll sizes up to 80” wide and custom panel sizes are available. We can manufacture rolls and flat panels in custom sizes to meet your production requirements. Generally, welded mesh is manufactured in rolls when wire diameters are smaller than .080” and in flat panels when wire sizes are over .080”.

We offer a full suite of conversion services including:

- Precision slitting

- Flush cut edges

- Random cut edges

- Annealing

- Precision shearing

- Straightening and flattening

Full inspection services are available if needed. Contact us today to learn more about our specialty alloy welded wire mesh products.

Dorstener’s expert staff will work with you to design and manufacture the welded wire mesh product that will meet your requirements and budget. All our high quality welded mesh products are manufactured to ISO 9001 standards.

Resources

Woven Wire Cloth Brochure

12-page sales brochure for Woven Wire Cloth with standard specifications (PDF)

Welded Wire Mesh Solutions

12-page sales brochure for Welded Wire Mesh with standard specifications (PDF)

SPECIFICATIONS FOR COMMON PLAIN AND TWILL WEAVE WIRE CLOTH

4-page specifications for Common Plain and Twill Weave Wire Cloth (PDF)

Specifications Plain Dutch and Twill Dutch Weave Filter Cloth

1-page specifications for Plain Dutch and Twill Dutch Weave Filter Cloth (PDF)

Specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth

1-page specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth (PDF)

Stainless Steel Woven Cloth Materials Chemistry

Nickel Based Alloy Woven Cloth Materials Chemistry

Copper, Brass, & Bronze Woven Cloth Materials Chemistry

ASTM E2016 Standard Specification for Industrial Woven Wire Cloth

This specification covers industrial woven wire fabric, referred to as wire cloth, for general use including the separation of particles. (purchase)

ASTM E2814 Standard Specification for Industrial Woven Wire Filter Cloth

This specification covers the special grade of industrial woven wire cloth, referred to as filter cloth, for general filtration including the separation of solids from fluids (liquids or gases), based on a desired particle size retention. Filter cloth can be made of any primary metal or metal alloy wire that is suitable for weaving. (purchase)

HAVE QUESTIONS OR NEED A QUOTE?

If you have any questions, need a quote or would like to receive more detailed information on our products and services, please contact us today. We are ready to serve you.

DORSTENER WIRE TECH

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(888) 931-9473 toll free

(281) 651-6226 local

(281) 651-6228 fax