Slitting Services

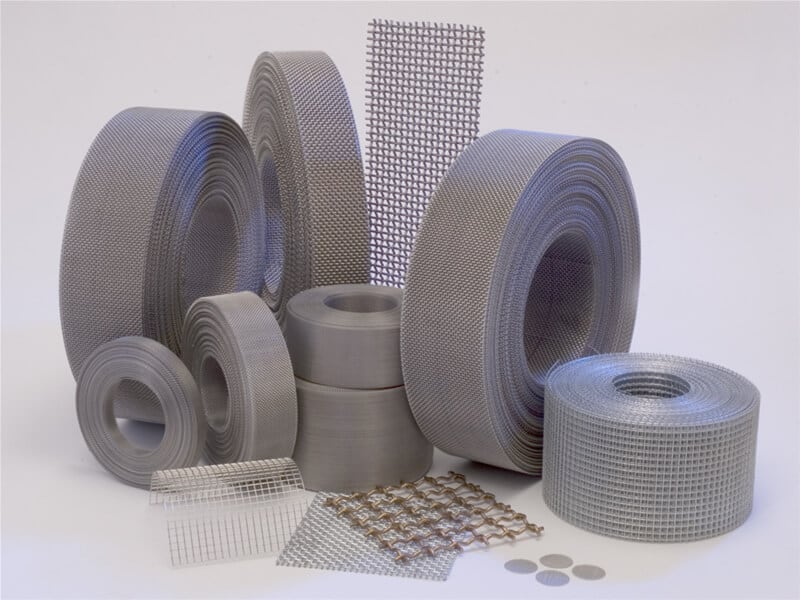

Dorstener Wire Tech provides a full range of slitting, cutting, cleaning and degreasing services for woven wire cloth and welded wire mesh. We employ various slitting methods, combining multiple lines of advanced machinery with wide-ranging material knowledge in order to provide cost-effective solutions. Dorstener Wire Tech is recognized as an industry leader in slitting and cutting mesh to size.

Our slitting services contribute to the manufacturing process of many products. Not only do our slitting services prevent frayed wires, but our services also help many of our customers save time and money.

Slit coils are a popular choice for clients that require their wire mesh ready for production, for such as filter elements or stamping operations. Slitting is a metal cutting process where large rolls or coils of sheet metal are cut using very sharp rotary blades. Once the coil runs through the slitter, circular blades make the cuts on the coil.

We can also wind your slit coils to increase your run times per coil. This process allows for less coil changes – meaning lower costs and faster production for your business. Whether it is galvanized, stainless, or welded mesh, Dorstener Wire Tech can slit your master coil to your exact specifications with our advanced machinery and expertise.

We guarantee to deliver slit wire cloth and mesh that meets our customers’ exact requirements. It is our goal to provide our clients with wire cloth and welded mesh that is finished and ready to go into production. No other company has the capability to process this service for a lower cost, with fast turn around and accuracies. Additionally, DWT is also known for providing the tightest tolerances in the industry.

- Chemical equipment

- Liquid filtration

- Oil well filter screens

- Pressure vessels

- Air filtration

- Solar Panel Protection

- Pest Control

- Security Screens, and more

Slitting Services Dimensional Verification

Our production department is fully capable to review in detail our customer’s order request in order to avoid production mistakes. Our team always performs a first article inspection, which is a dimensional verification on the first produced part. Not only that, we also conduct in process inspections and final quality controls in order to ensure that the products meet your requirements.

Cleaning & degreasing services

Dorstener’s ultrasonic cleaning services provide your wire cloth and welded mesh free of dirt and oil. We can clean the cloth and mesh whether it is delivered in rolls, coils or cut parts. Cleaned mesh is packaged to prevent contamination during transit and warehousing, ensuring the cloth is clean for production.

If your wire mesh and welded wire cloth requires finishing to ensure it is ready for your production line, Dorstener Wire Tech can provide expert cutting, shearing, slitting and cleaning services. Your mesh will be delivered to you ready for production, when you need it.

Conversion Capabilities

Slit sizes – ½ inch wide or larger

Slit tolerances – standard of +/- .030”, however tighter tolerances are available, depending on the mesh.

Core size – 3 inch & 6 inch inside diameters. Please note, coils are available with or without cardboard coils.

Coil length – up to 2,000 linear feet, depending on the mesh.

Dorstener is ISO 9001 Certified, and all our manufacturing processes meet the highest quality standards. All products can be manufactured in accordance with the DIN, ASTM and ISO standards required by our clients. In addition, DWT’s woven wire cloth and welded wire mesh products can be ordered to meet DFAR and other military standards.

Our staff is available to help you with slitting services and our other capabilities that will meet your design requirements and budget. Contact us today for more information about our slitting services.

HAVE QUESTIONS OR NEED A QUOTE?

If you have any questions, need a quote or would like to receive more detailed information on our products and services, please contact us today. We are ready to serve you.

DORSTENER WIRE TECH

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(888) 931-9473 toll free

(281) 651-6226 local

(281) 651-6228 fax