Sieving, Sifting & Sizing Applications

Precision Wire Mesh & Wire Cloth for Sieving, Sifting & Sizing

Dorstener Wire tech manufactures wire cloth for sieving, sifting & sizing applications. For the characterization of bulk goods of different forms and sizes, the knowledge of their particle size distributions is essential. The particle size distribution, i.e. the number of particles of different sizes, is responsible for important physical and chemical properties such as solubility, flowability and surface reaction.

In many industries such as food, pharmaceutics and chemistry traditional sieve analysis is the standard for production and quality control of powders and granules. Advantages of the sieve analysis include easy handling, low investment costs, precise and reproducible results in a comparably short time and the possibility to separate the particle size fractions. Therefore, this method is an accepted alternative to analysis methods using laser light or image processing.

From sieving brewer’s yeast in breweries, the sizing of coffee beans, the removal of oversized lumps and particles, the separation of curds and whey in cheese production to the coarse cleaning of fluids, DWT screens offer solutions for a wide range wire cloth sieving, sifting & sizing processes and procedures.

Choosing the right screen is almost as important as choosing the right industrial separation equipment. Dorstener Wire Tech has revolutionized the screening world by providing high quality precision mesh to the leading US manufacturers of industrial separation equipment. You can depend on Dorstener Wire Tech for precision wire cloth for your sieving, sifting & sizing applications.

Sieving, Sifting & Sizing Applications

Here are some examples of the sieving, sifting & sizing applications that Dorstener metal is used for:

- Agriculture

- Biofuel

- Chemical

- Ceramics

- Fertilizer

- Food & Beverage

- Frac Sand

- Minerals

- Oil & Gas Mud Screens

- Plastics

- Powder Bulk

- Pharmaceutical

- Recycling

- Water Treatment

Here is an example of sieving. To sieve is to separate a mixture. A vibrating screen “shale shaker” on an oil drilling rig sieves drilling fluids, called mud, from the drill bit cuttings circulated up and out of the well bore. The fluid is then circulated back down the well bore to cool the bit and bring more cuttings to the surface.

Dorstener is ISO 9001 Certified, and all our products are manufactured to the highest quality standards. Our staff is available to help you design the sieving, sifting, and sizing wire mesh product that will meet your design requirements and budget. Contact us today for more information about our wire mesh used in sieving, sifting, and sizing applications.

Resources

Woven Wire Cloth Brochure

12-page sales brochure for Woven Wire Cloth with standard specifications (PDF)

Welded Wire Mesh Solutions

12-page sales brochure for Welded Wire Mesh with standard specifications (PDF)

SPECIFICATIONS FOR COMMON PLAIN AND TWILL WEAVE WIRE CLOTH

4-page specifications for Common Plain and Twill Weave Wire Cloth (PDF)

Specifications Plain Dutch and Twill Dutch Weave Filter Cloth

1-page specifications for Plain Dutch and Twill Dutch Weave Filter Cloth (PDF)

Specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth

1-page specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth (PDF)

Stainless Steel Woven Cloth Materials Chemistry

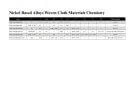

Nickel Based Alloy Woven Cloth Materials Chemistry

Copper, Brass, & Bronze Woven Cloth Materials Chemistry

ASTM E2016 Standard Specification for Industrial Woven Wire Cloth

This specification covers industrial woven wire fabric, referred to as wire cloth, for general use including the separation of particles. (purchase)

ASTM E2814 Standard Specification for Industrial Woven Wire Filter Cloth

This specification covers the special grade of industrial woven wire cloth, referred to as filter cloth, for general filtration including the separation of solids from fluids (liquids or gases), based on a desired particle size retention. Filter cloth can be made of any primary metal or metal alloy wire that is suitable for weaving. (purchase)

HAVE QUESTIONS OR NEED A QUOTE?

If you have any questions, need a quote or would like to receive more detailed information on our products and services, please contact us today. We are ready to serve you.

DORSTENER WIRE TECH

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(888) 931-9473 toll free

(281) 651-6226 local

(281) 651-6228 fax