Polymer Filtration Market

The plastics and polymer industry requires many different filters to insure a clean melt stream. Our metal polymer filtration screens are engineered to fit all styles and types of melt pumps and screen changers. The end goal of our product is to insure the final quality of your product.

The most common screen changers for melt filtration use single or multilayer wire cloth extruder screens. We produce these in round discs, rectangular or kidney shaped screens. The construction of the screen pack is critical to process performance and final product quality. Mesh combinations are carefully chosen to achieve a high strength pack that provides desired filtration levels and optimal throughput. To assist in the production of sensitive or high value polymers we offer frame pack screens for superior sealing and control.

Many screen changers (for example… virgin resin or film production) use cylindrical wire cloth filters of different complexities. For the separation and removal of small particles or gels from the melt stream, we produce cylindrical filter elements of sintered wire cloth or pleated metal fiber felt from 1-75 micron.

For plastics recycling we produce inexpensive food grade stainless steel and carbon steel filters for the extrusion process. Strong wire cloth belts with special weave patterns and edge treatments are commonly used in continuous screen changers.

Polymer Filtration Market Applications

Here are some examples in the polymer filtration market that Dorstener metal is used for;

- Extrusion

- Compounding

- Recycling

- Food Grade Recycling

- Blow Film

- Sheet Extrusion

- Profile Extrusion

- Melt Pump Filters

- Polymer Candle Elements

- Continues Melt Filters

- Synthetic Fiber Production

- Carpet Recycling

- Post Consumer Recycling

- Industrial Scrap Recycling

Resources

Polymer Filtration Products Brochure

8-page Sales brochure for Polymer Filtration Products with specifications (PDF)

Woven Wire Cloth Brochure

12-page sales brochure for Woven Wire Cloth with standard specifications (PDF)

Welded Wire Mesh Solutions

12-page sales brochure for Welded Wire Mesh with standard specifications (PDF)

SPECIFICATIONS FOR COMMON PLAIN AND TWILL WEAVE WIRE CLOTH

4-page specifications for Common Plain and Twill Weave Wire Cloth (PDF)

Specifications Plain Dutch and Twill Dutch Weave Filter Cloth

1-page specifications for Plain Dutch and Twill Dutch Weave Filter Cloth (PDF)

Specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth

1-page specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth (PDF)

Stainless Steel Woven Cloth Materials Chemistry

Stainless Steel Woven Cloth Materials Chemistry (PDF)

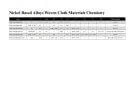

Nickel Based Alloy Woven Cloth Materials Chemistry

Nickel Based Alloy Woven Cloth Materials Chemistry (PDF)

Copper, Brass, & Bronze Woven Cloth Materials Chemistry

Copper, Brass, & Bronze Woven Cloth Materials Chemistry (PDF)

ASTM E2016 Standard Specification for Industrial Woven Wire Cloth

This specification covers industrial woven wire fabric, referred to as wire cloth, for general use including the separation of particles. (purchase)

ASTM E2814 Standard Specification for Industrial Woven Wire Filter Cloth

This specification covers the special grade of industrial woven wire cloth, referred to as filter cloth, for general filtration including the separation of solids from fluids (liquids or gases), based on a desired particle size retention. Filter cloth can be made of any primary metal or metal alloy wire that is suitable for weaving. (purchase)

HAVE QUESTIONS OR NEED A QUOTE?

If you have any questions, need a quote or would like to receive more detailed information on our products and services, please contact us today. We are ready to serve you.

DORSTENER WIRE TECH

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(888) 931-9473 toll free

(281) 651-6226 local

(281) 651-6228 fax