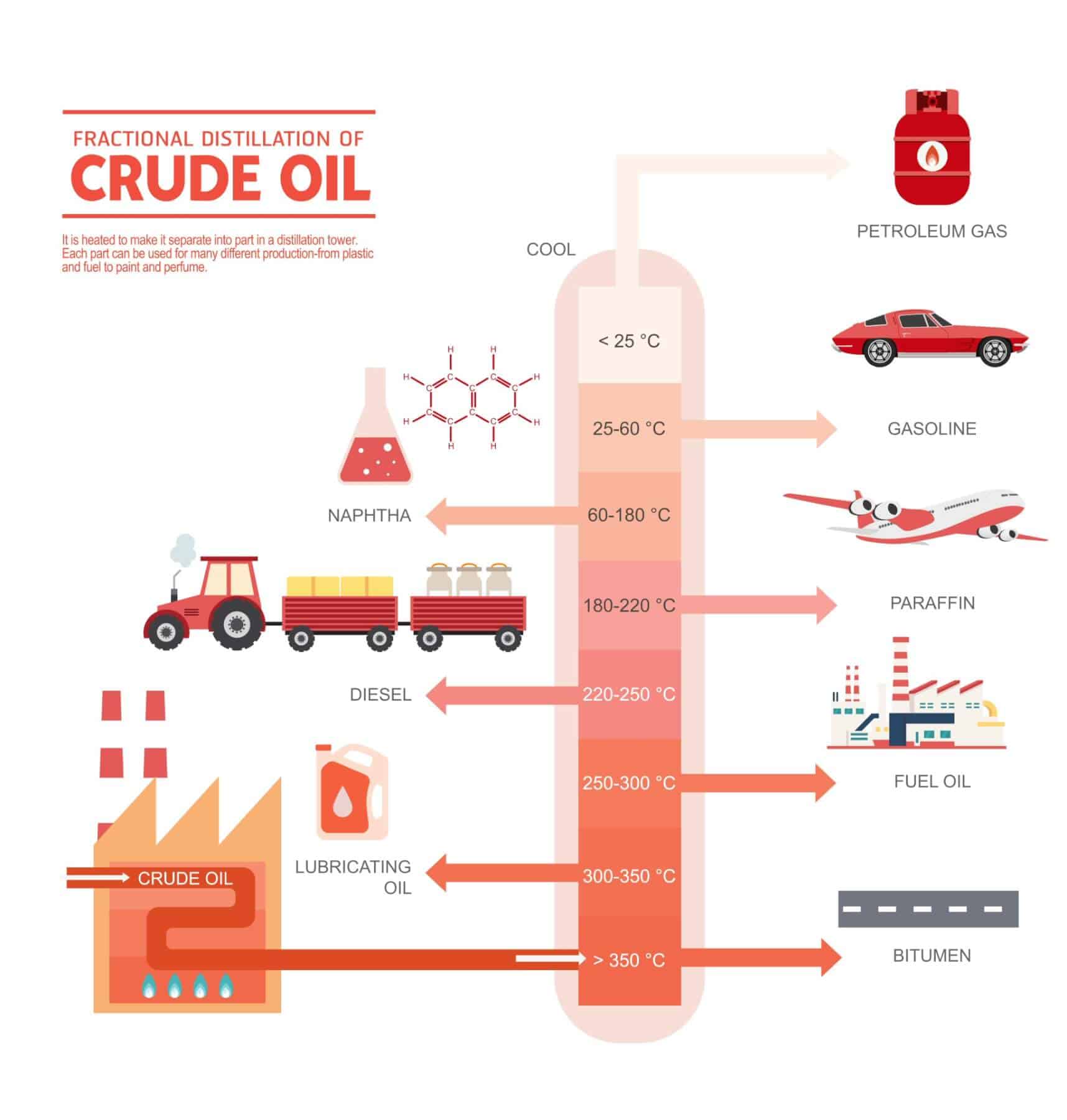

Crude Oil Processing Applications

Filtration equipment in petroleum refineries are used to separate catalyst fines from slurry oil by using sintered metal mesh porous screens to achieve the long term service of catalyst. Slurry oil filtration is performed by using durable filter screens. The filtration media inhibits the removal of downstream catalyst contamination. Use of sintered mesh is a reliable way to achieve good quality slurry oil by decreasing catalyst concentration. The sintered mesh can be backwash cleaned. Elimination of fines enhances the product yield, increasing the price value of filtered product and also limits the wear and tear of downstream equipment besides to enhancing the catalyst recover and handling process.

Dorstener Wire Tech filtration media for crude oil development is centered around sintered wire mesh. Laminated woven wire mesh provides a physically accurate opening for consistent and reliable filtration. Dorstener Wire Tech has the technology to manufacture the highest quality media and can provide data certifying the strength and alloy. Dorstener Wire Tech can provide fully completed components and semi-finished medias for crude oil processing applications.

Crude Oil Processing Applications

Dorstener provides wire cloth filters that help solve challenging issues in crude oil processing and refining.

- High porosity crude oil refining filters

- Sintered filters for crude oil processing

- Cleanable crude oil filters

- Backflush crude oil filters

- Replacement filters for oil refining and processing

Catalyst Support Screens

Dorstener Wire Tech produces a wide range of catalyst support screens and grids for the petrochemical and refining industries. Wire mesh support screens allow for more open area and more precise openings than perforated steel or wedge wire screens. As a result, catalyst support screens manufactured using wire mesh are more efficient.

Wire Mesh Support Screens

Manufactured using our high quality woven and wire mesh, our custom catalyst support screens include the following options:

- Mesh cut to size for manway openings

- Stitched or welded seams

- Custom patterns that meet your requirements

- Bolt holes for hold down rings.

- Wide range of openings, from ½” down to 5 microns

- Wide range of alloys, including 304ss and 316ss stainless steel and other nickel-based alloys

DWT has a wide variety of woven and welded mesh available to provide fast turn-around for crude oil processing projects. Custom weaves and mesh are available for specialty products.

Resources

Woven Wire Cloth Brochure

12-page sales brochure for Woven Wire Cloth with standard specifications (PDF)

Welded Wire Mesh Solutions

12-page sales brochure for Welded Wire Mesh with standard specifications (PDF)

SPECIFICATIONS FOR COMMON PLAIN AND TWILL WEAVE WIRE CLOTH

4-page specifications for Common Plain and Twill Weave Wire Cloth (PDF)

Specifications Plain Dutch and Twill Dutch Weave Filter Cloth

1-page specifications for Plain Dutch and Twill Dutch Weave Filter Cloth (PDF)

Specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth

1-page specifications for Reverse Plain Dutch and Reverse Dutch Twill Weave Filter Cloth (PDF)

Stainless Steel Woven Cloth Materials Chemistry

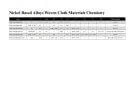

Nickel Based Alloy Woven Cloth Materials Chemistry

Copper, Brass, & Bronze Woven Cloth Materials Chemistry

ASTM E2016 Standard Specification for Industrial Woven Wire Cloth

This specification covers industrial woven wire fabric, referred to as wire cloth, for general use including the separation of particles. (purchase)

ASTM E2814 Standard Specification for Industrial Woven Wire Filter Cloth

This specification covers the special grade of industrial woven wire cloth, referred to as filter cloth, for general filtration including the separation of solids from fluids (liquids or gases), based on a desired particle size retention. Filter cloth can be made of any primary metal or metal alloy wire that is suitable for weaving. (purchase)

HAVE QUESTIONS OR NEED A QUOTE?

If you have any questions, need a quote or would like to receive more detailed information on our products and services, please contact us today. We are ready to serve you.

DORSTENER WIRE TECH

Physical Address

19994 Hickory Twig Way

Spring, TX 77388 USA

Mailing Address

P.O. Box 3019

Spring, TX 77383

PHONE

(888) 931-9473 toll free

(281) 651-6226 local

(281) 651-6228 fax